Hagfish Slime Sparks a Sustainable Materials Revolution

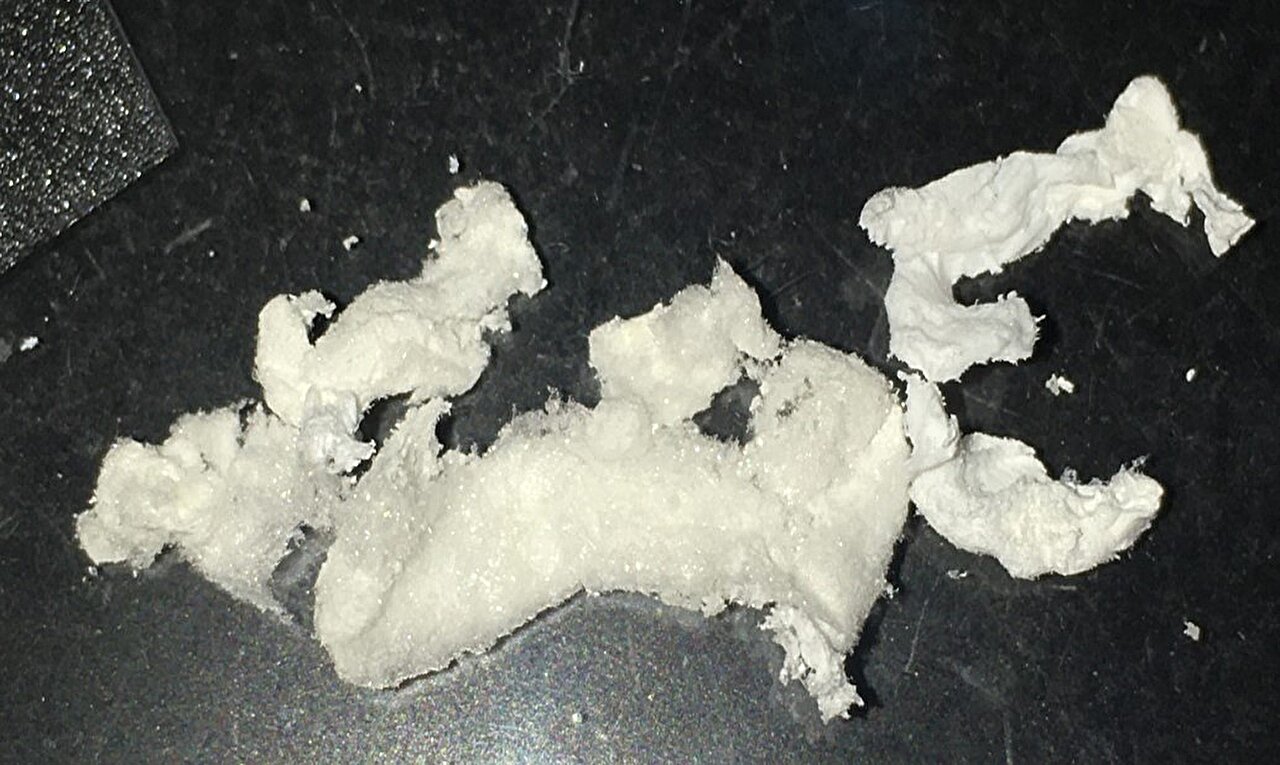

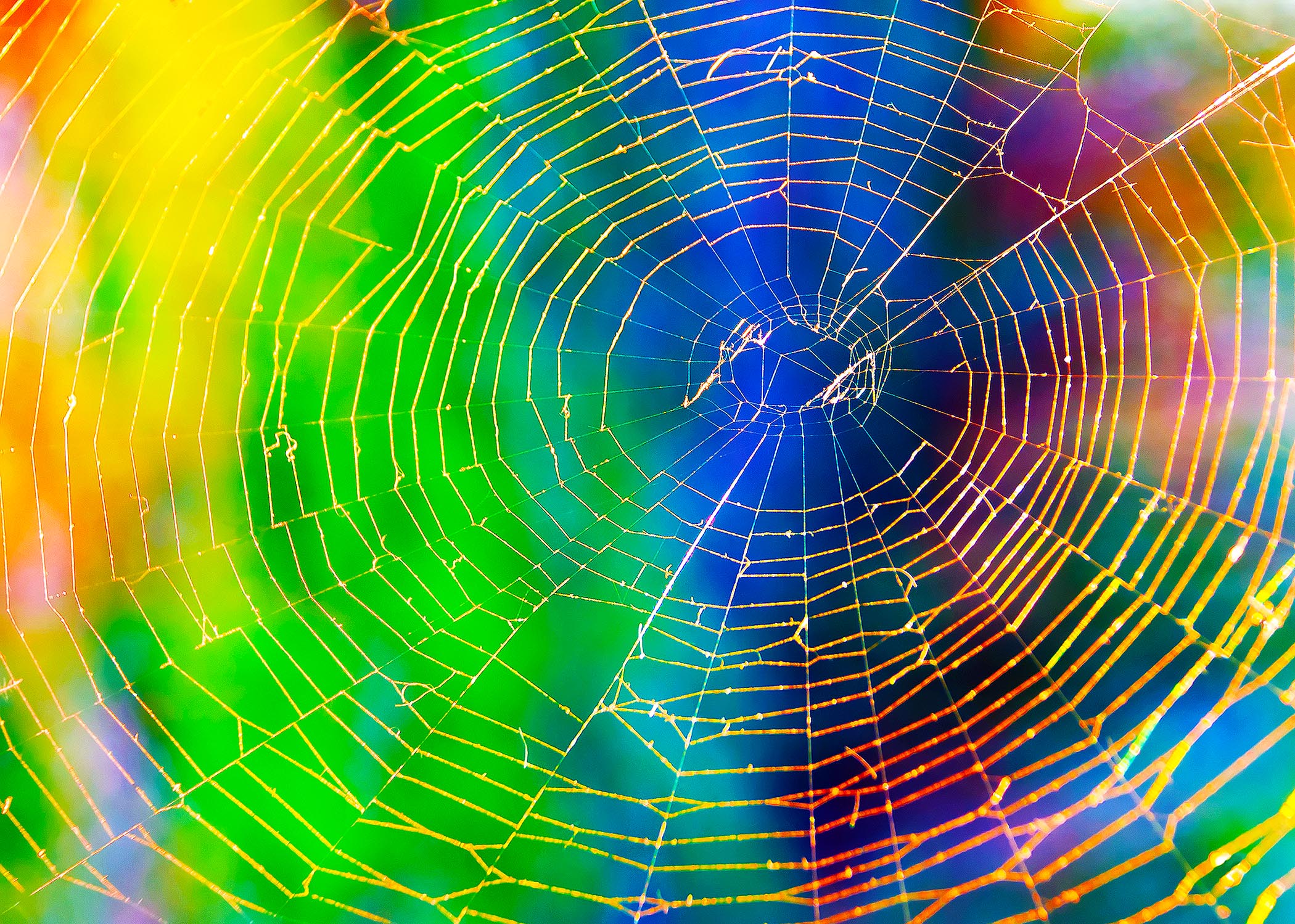

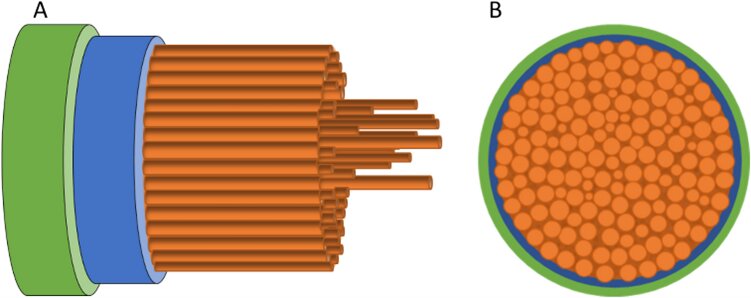

Hagfish slime rapidly expands into a dense gel when seawater is present, using ultra-thin protein threads that self-assemble into a fibrous network and can clog predators’ gills in seconds. Produced at room temperature in seawater with no toxic byproducts, this slime is inspiring researchers to develop sustainable biomaterials—self-assembling fibers that could rival spider silk. Scientists aim to isolate the slime proteins’ genes for production in microbes, but scaling, control of assembly, and durability remain key hurdles.