MIT’s Biodegradable Capsule Confirms Medication Ingestion in Real Time

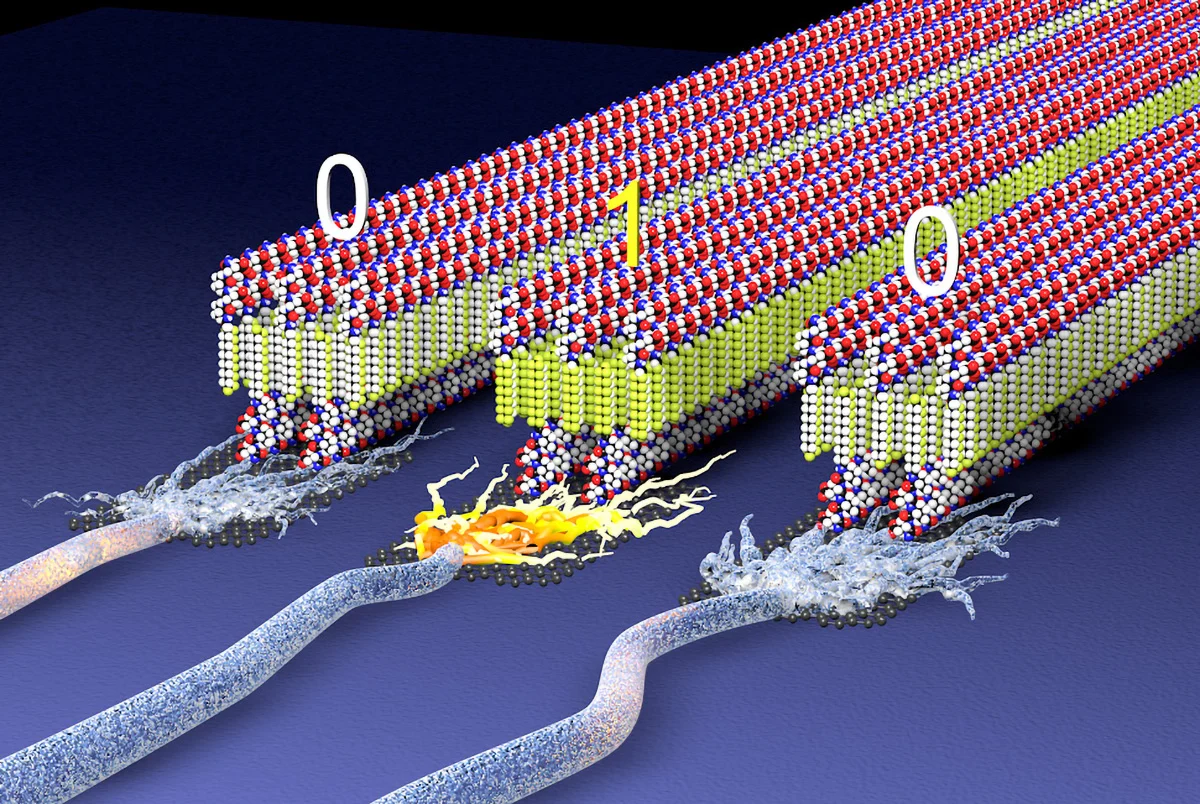

MIT engineers have developed a biodegradable ingestible capsule with a zinc-cellulose antenna and a micro-RFID chip that emits a real-time signal confirming a pill has been swallowed. The capsule dissolves in the stomach while the RFID component is excreted, enabling noninvasive adherence monitoring for critical therapies (e.g., transplant immunosuppression) and potential integration with health records. The SAFARI project uses safe, eco-friendly materials and aims for human trials, offering a pathway to real-time feedback without bulky wearables.