Innovative Lightweight Polymer Films for Enhanced Corrosion Protection

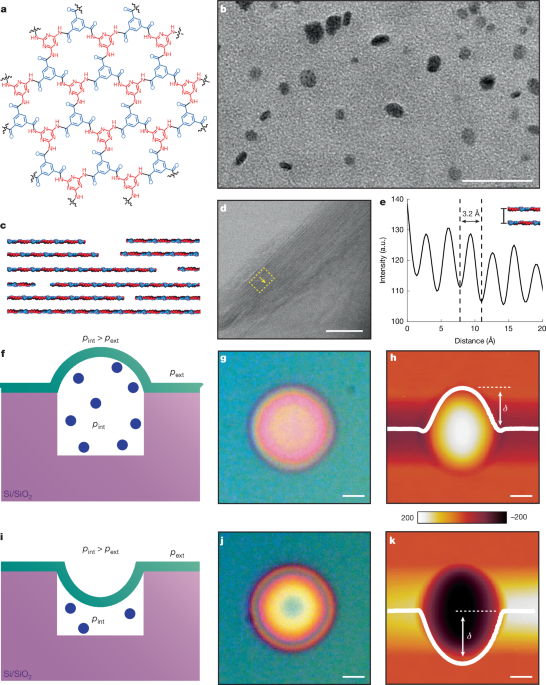

Researchers developed a highly impermeable, molecularly stable polymer from two-dimensional polyaramids, characterized by advanced microscopy, spectroscopy, and gas adsorption techniques, demonstrating its potential for barrier applications due to its robust amide bonds and ordered structure.