Helium hiccup delays Artemis II lunar mission, prompting a rollback to the VAB

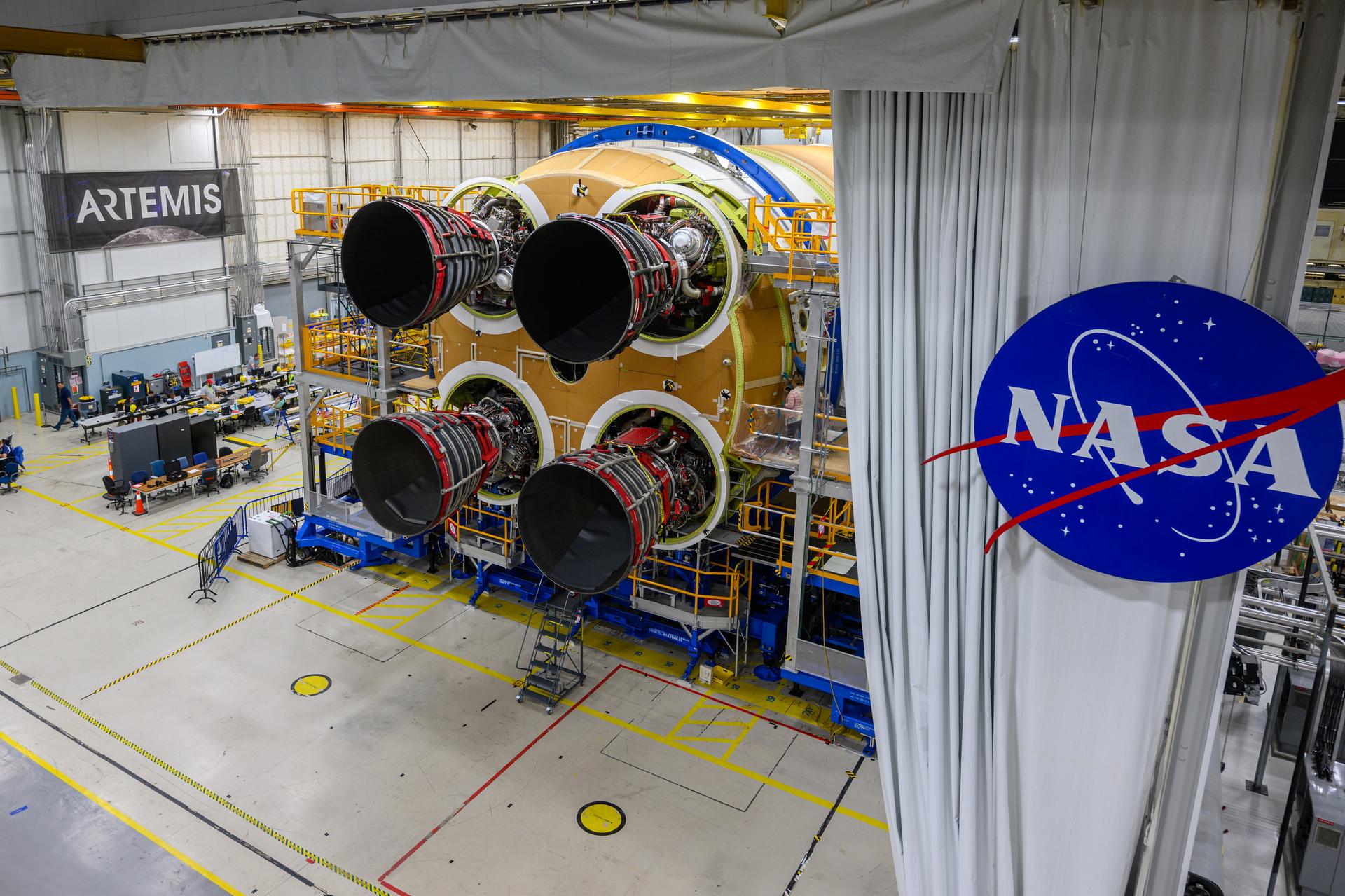

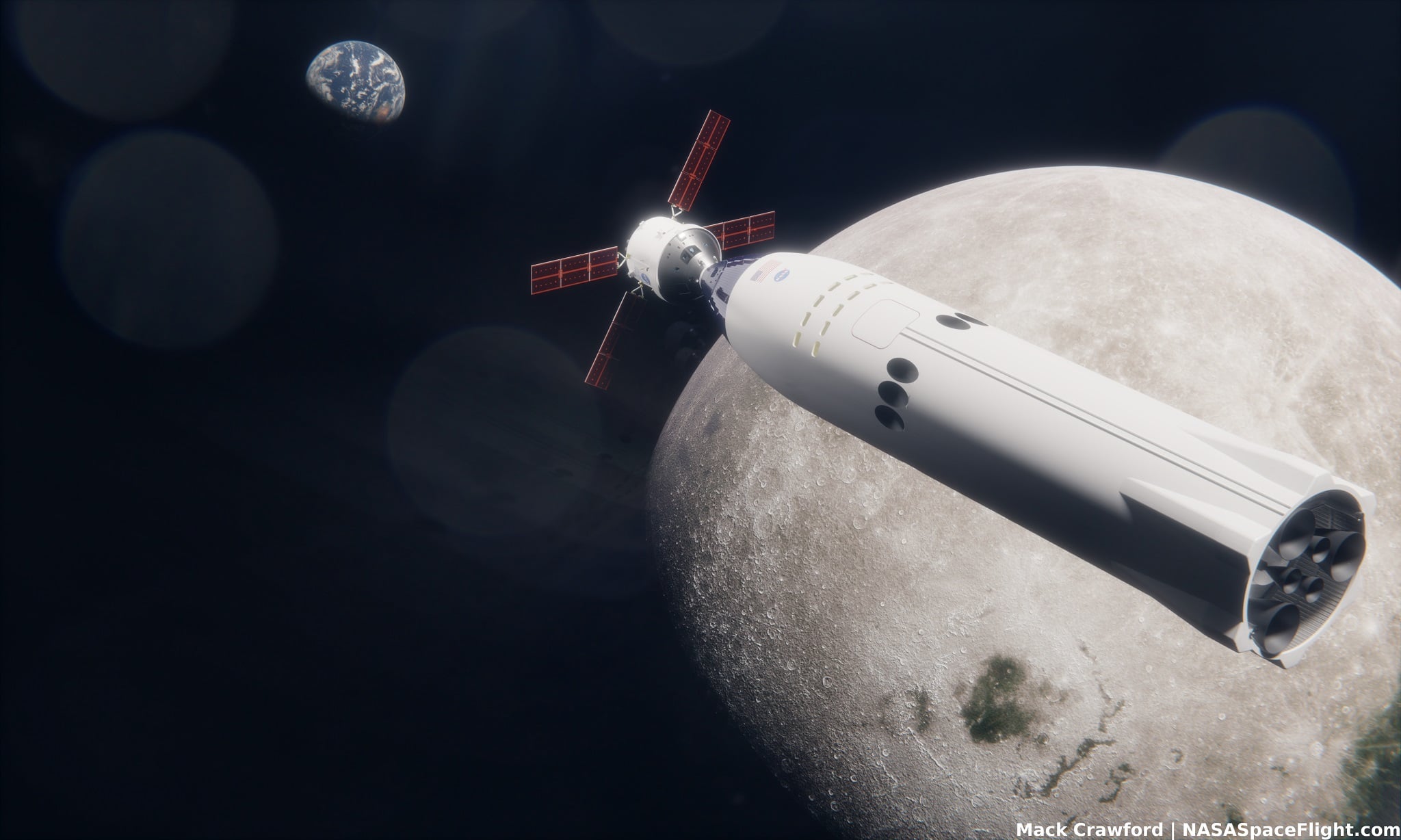

NASA’s Artemis II crewed lunar mission hit a new snag after engineers detected a helium flow problem in the upper stage of the Space Launch System, forcing the rocket to roll back from the launchpad to the Vehicle Assembly Building. The setback likely ends any March launch plans and sets no-earlier-than April as the earliest window, with potential dates in May or June under consideration depending on data, repairs, and any further testing. The mission would carry four astronauts—Reid Wiseman, Victor Glover, Christina Koch, and Canadian Jeremy Hansen—on a roughly 10-day lunar flyby, a first for humans in deep space since Apollo. Officials are still diagnosing the helium issue, weighing possible causes (e.g., a faulty filter, valve, or quick-disconnect) and whether another wet dress rehearsal will be required before a new launch date can be set.