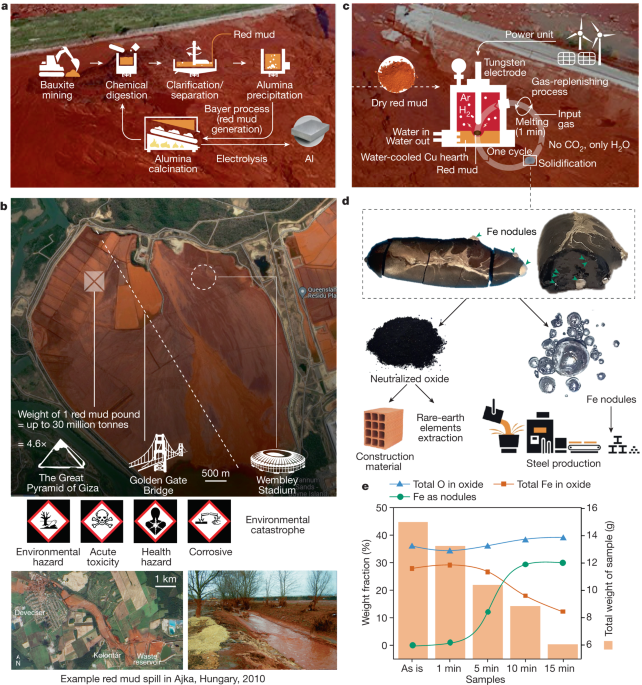

"Transforming Aluminum Mining Waste into Climate-Friendly Green Steel"

Researchers in Germany have developed a method to extract iron and potentially other metals from the waste generated during aluminum production, known as red mud, using hydrogen and electricity sourced from renewable power. This process could potentially lead to the production of "green steel" with significantly lower carbon emissions. While the method reduces the environmental impact of the waste and neutralizes its pH, it is energy-intensive and economically challenging due to the cost of energy required. Nonetheless, the low carbon emissions make it a promising avenue for sustainable metal production.