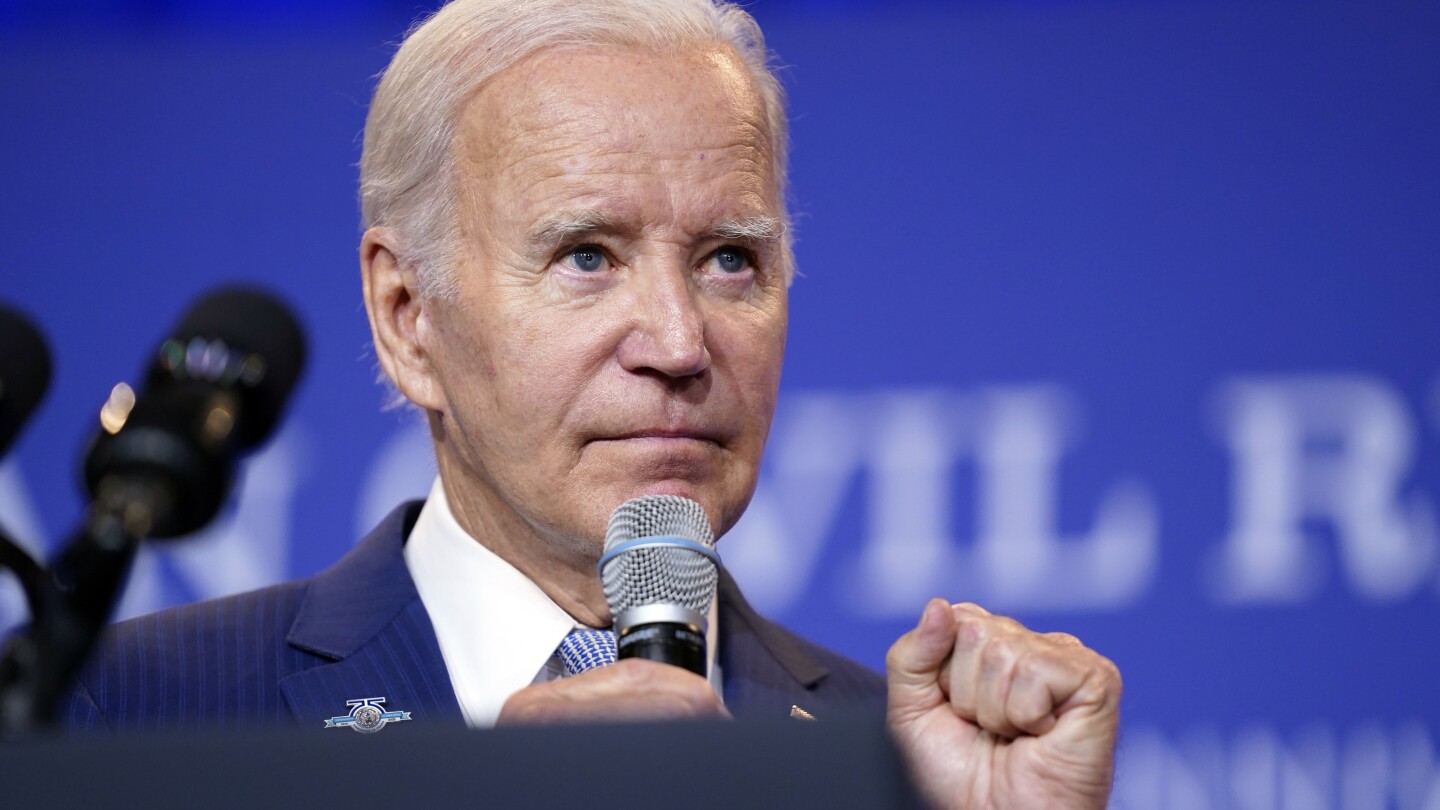

Trump taps DPA to bolster U.S. glyphosate and phosphorus production

President Trump invoked the Defense Production Act to boost domestic production of elemental phosphorus and glyphosate-based herbicides (Roundup), citing defense and food security; the move aligns with the Make America Healthy Again stance amid ongoing controversy and lawsuits over glyphosate's health effects, and tasks the Agriculture Secretary with implementing expanded production while highlighting U.S. reliance on limited domestic producers and potential supply-chain vulnerabilities.