Advancements in Rocket Nozzle Technology Propel NASA's Deep Space Missions

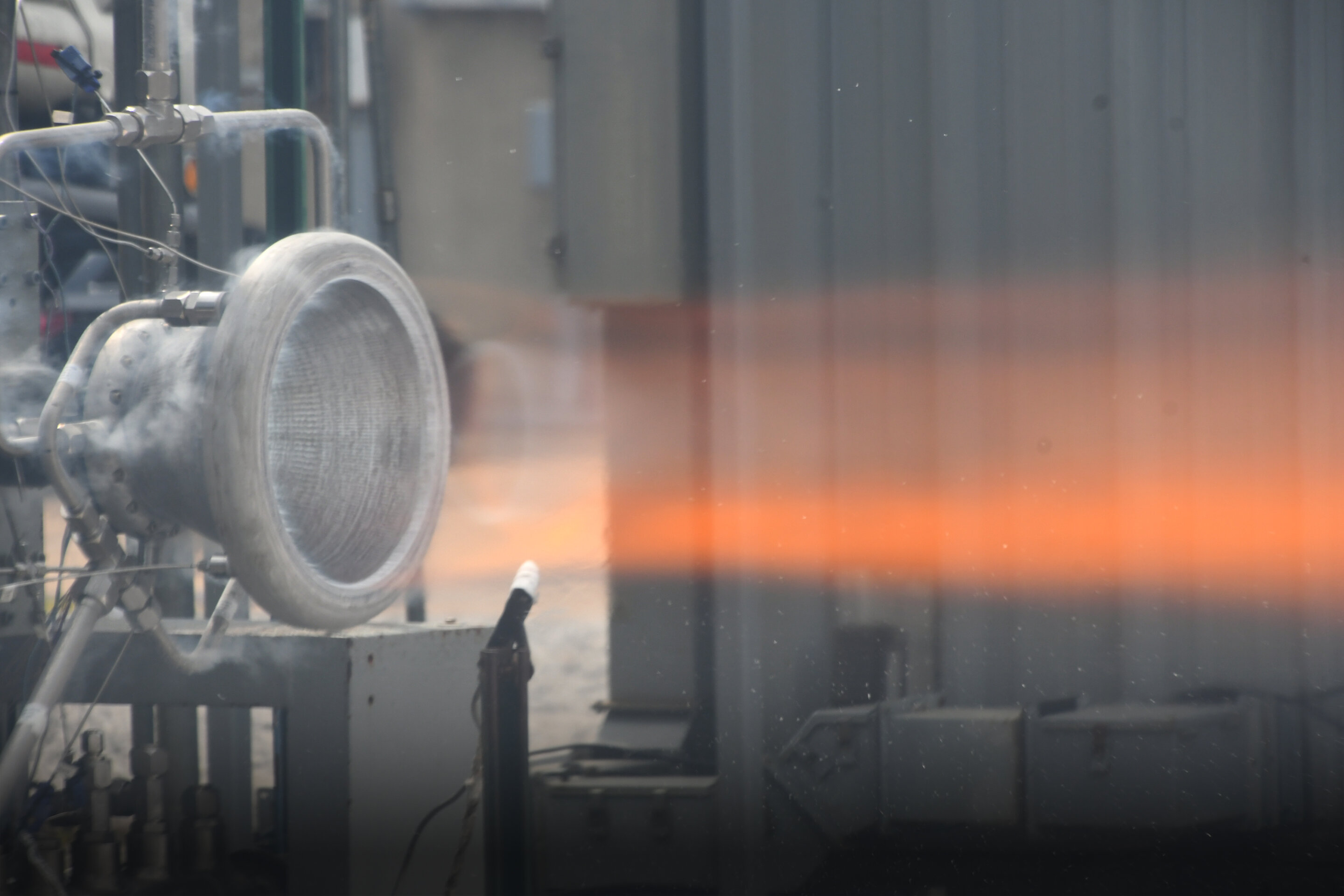

NASA has successfully built and tested a 3D printed rocket engine nozzle made of aluminum, which is lighter than conventional nozzles and has the potential to enable deep space flights with increased payload capacity. The nozzle, developed under the RAMFIRE project, utilizes a novel aluminum alloy that is heat resistant and weldable, overcoming the challenges associated with using aluminum for additive manufacturing of rocket engine parts. This advancement in lightweight, additively-manufactured aluminum rocket nozzles could contribute to NASA's objectives of sending more cargo to deep space destinations and support future missions to the moon, Mars, and beyond.

- NASA's innovative rocket nozzle paves way for deep space missions Phys.org

- RAMFIRE Nozzle Hot Fire Test NASA's Marshall Space Flight Center

- NASA 3D prints aluminum RAMFIRE rocket engine nozzles to enable deep space exploration 3D Printing Industry

- This New 3D Printable Wonder Material Could Help Propel NASA’s Future Missions Into Deep Space The Debrief

- NASA's Innovative Rocket Nozzle Paves Way for Deep Space Missions NASA

- View Full Coverage on Google News

Reading Insights

0

1

3 min

vs 4 min read

87%

762 → 97 words

Want the full story? Read the original article

Read on Phys.org