NASA develops 3D-printed superalloy for extreme environments and nuclear space travel.

TL;DR Summary

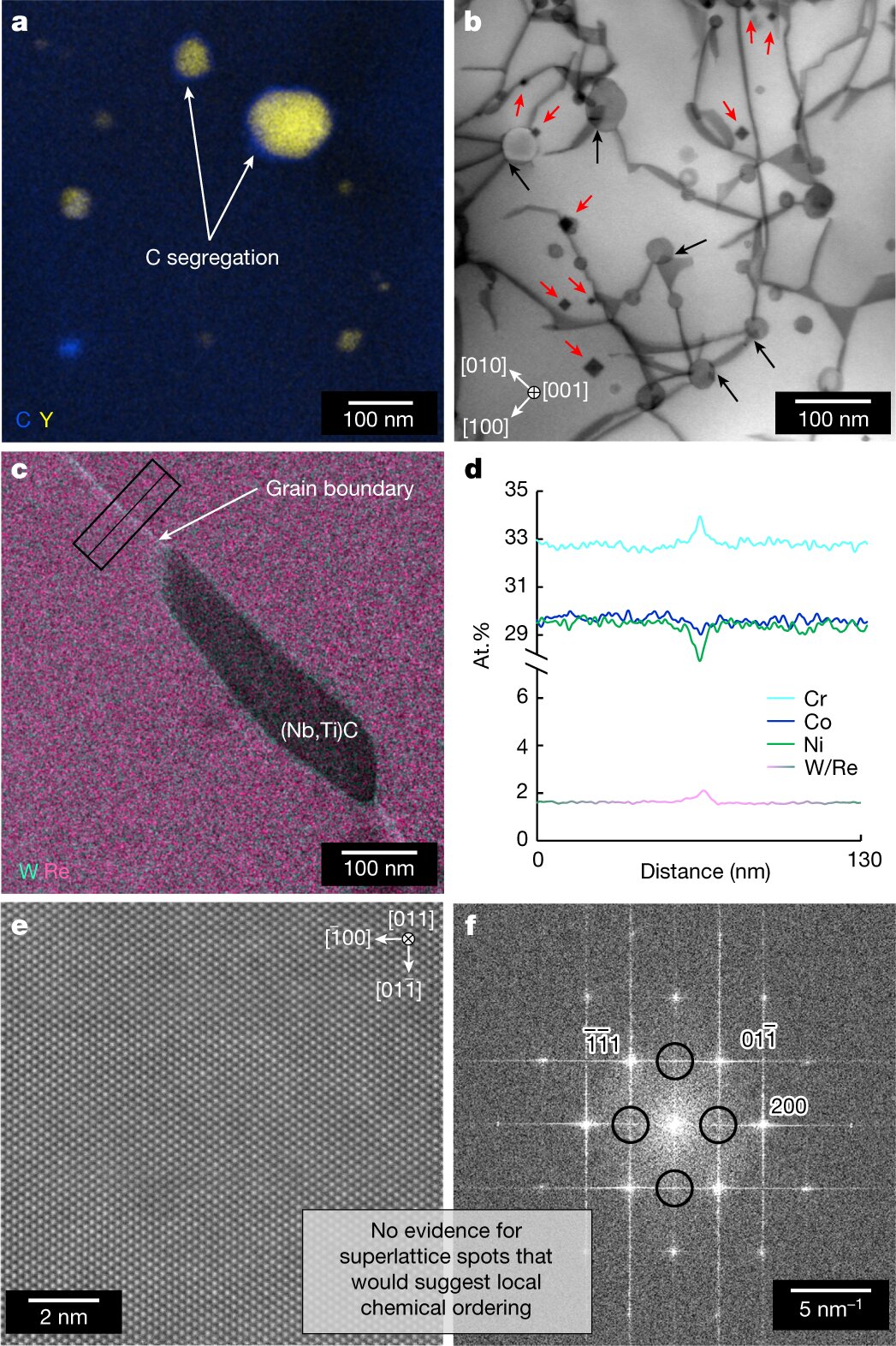

A team of materials scientists from NASA, The Ohio State University, and HX5 LLC have developed a 3D printing process that produces an alloy called GRX-810, which is much more resistant to stress than other alloys currently in use. The process involves adding a dusting of yttrium oxide powder to each layer of ink made of a mixture of cobalt, nickel, and chrome particles. The new alloy lasted for 6,500 hours in a creep test, compared to current top materials that typically last approximately 10 hours.

Reading Insights

Total Reads

0

Unique Readers

1

Time Saved

2 min

vs 3 min read

Condensed

85%

580 → 86 words

Want the full story? Read the original article

Read on Phys.org