"Boeing Faces Further Production Delays Due to 737 Fuselage Issues"

Boeing has reported a new problem with the fuselages of its 737 aircraft, adding to the list of issues the company has faced with its popular jetliners.

All articles tagged with #737

Boeing has reported a new problem with the fuselages of its 737 aircraft, adding to the list of issues the company has faced with its popular jetliners.

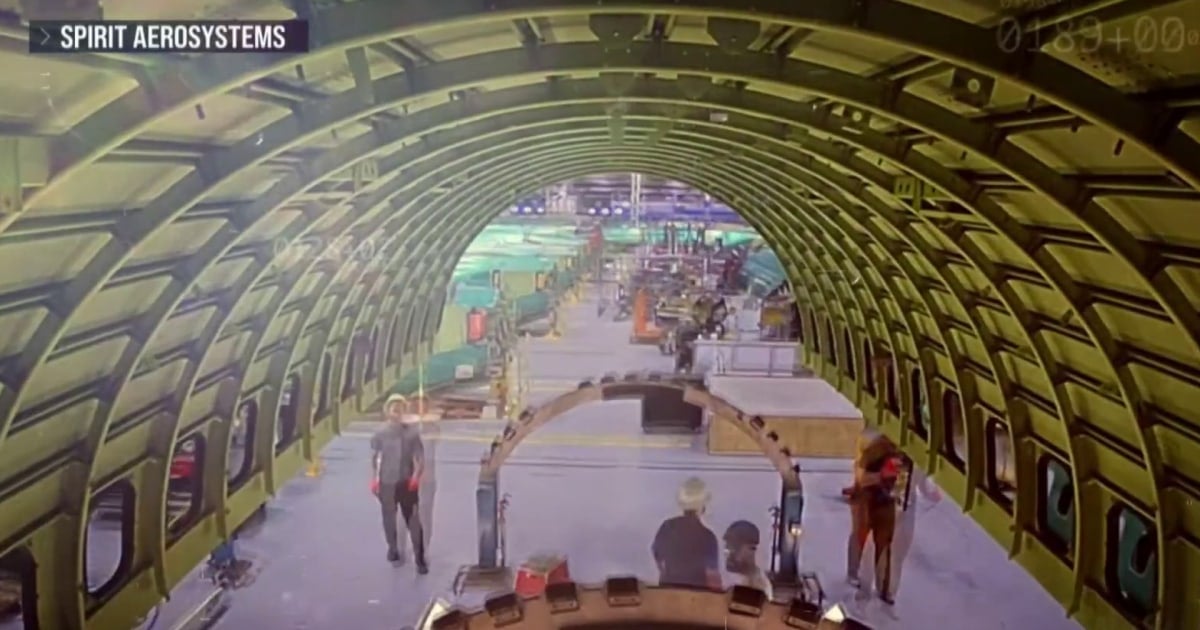

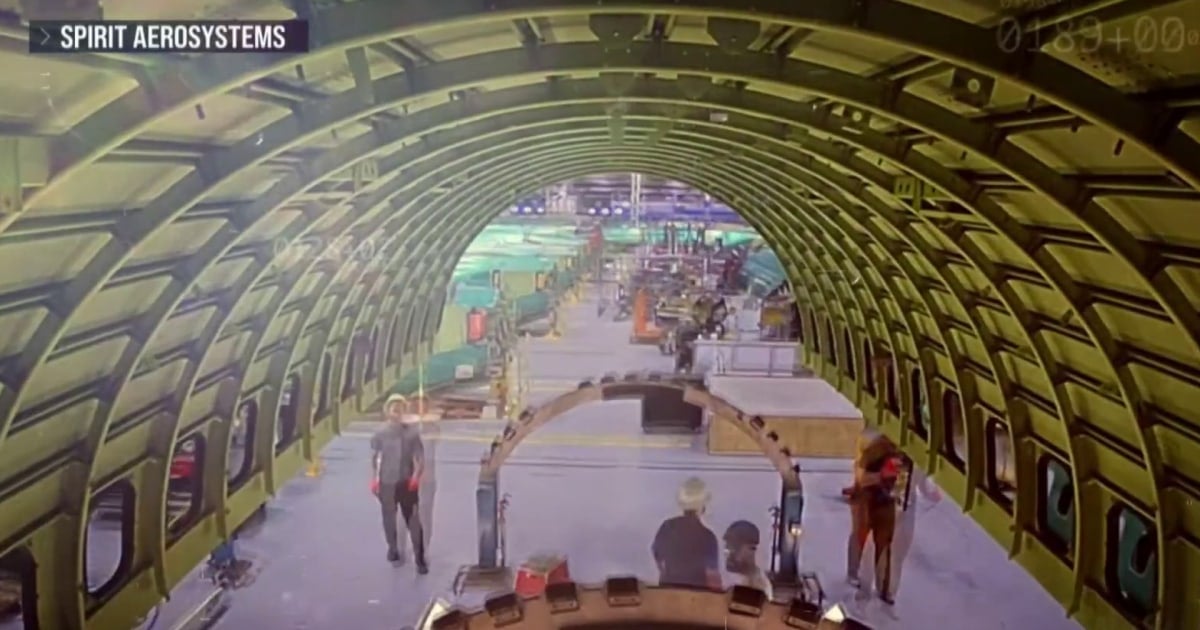

Boeing has found "non-conformance" in the way some holes were drilled in about 50 undelivered 737 jets, prompting the need for rework on these planes. While not an immediate flight safety issue, the company has been under scrutiny since a door plug fell out of a 737 Max 9 in January, leading the FAA to increase its oversight and begin an immediate audit of Boeing's production and manufacturing.

Boeing will rework about 50 737 planes at its Renton factory due to a nonconformance issue flagged by a supplier regarding the drilling of two holes in the fuselages, which is not an immediate flight safety issue but requires inspections and rework. This could lead to delays in near-term 737 deliveries, but Boeing is committed to delivering perfect airplanes every time.

Boeing has delayed the delivery of 50 of its 737s due to a new 'non-conformance' issue discovered at its Renton facility, following a previous halt in production to address a MAX-9 door plug blowout. The company informed employees about the latest issue in an internal memo, stating that all fuselages at the facility will be inspected before the delay is over. While the issue is not an immediate flight safety concern, rework will be required on the affected airplanes, and the company is dedicating several days to address the issue.

PMDG has announced that the release date for the Universal Flight Tablet is set, although the specific date has not been shared yet. Previews for the tablet will be available soon. The development of the 777 has been slightly delayed due to team members being unwell or dealing with personal matters, but it is expected to enter beta testing soon. Additionally, PMDG is working on a new update for the DC-6 to address gyropilot tracking issues.

Boeing's CFO, Brian West, stated that the company will still meet its target of delivering at least 400 narrowbody 737s this year, despite a recent production flaw that has slowed down deliveries of the 737 MAX. However, Boeing will be on the lower end of its delivery target, and margins for its commercial airplanes business will be negative in the third quarter due to low deliveries and higher development costs. The production problem involves improperly drilled fastener holes on the 737 aft pressure bulkhead, requiring rework on about 75% of the 220 affected aircraft. The fix is expected to be time-consuming and may extend beyond November.

A Boeing 737 was forced to make an emergency landing after one of its engines was struck by a flock of birds shortly after takeoff. The incident highlights the ongoing safety concerns surrounding bird strikes in aviation.