Overcoming Metal 3D-Printing Challenges for Widespread Use

TL;DR Summary

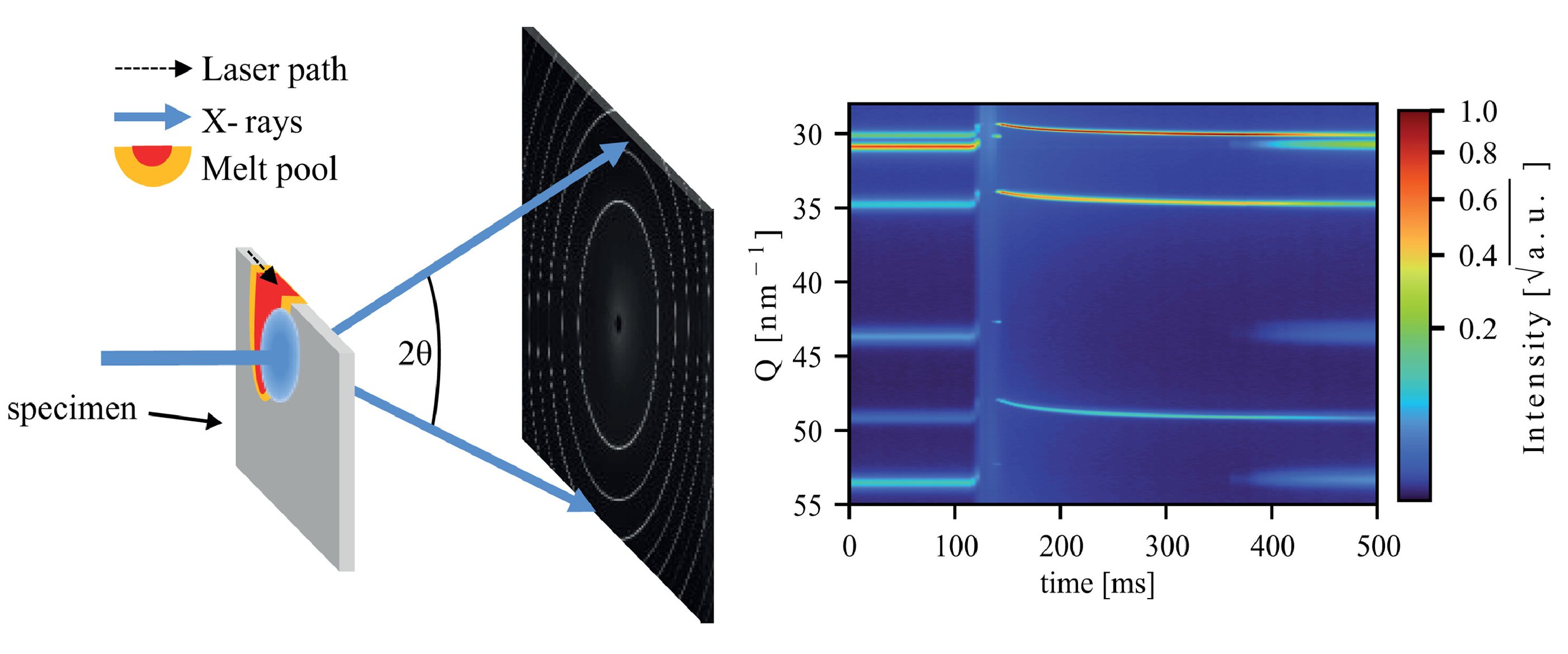

Researchers at the National Institute of Standards and Technology (NIST) and KTH Royal Institute of Technology in Sweden have used high-speed X-ray diffraction to identify the crystal structures that form within steel as it is 3D-printed. The findings unlock a computational tool for 3D-printing professionals, offering them a greater ability to predict and control the characteristics of printed parts, potentially improving the technology's consistency and feasibility for large-scale manufacturing.

Reading Insights

Total Reads

0

Unique Readers

1

Time Saved

5 min

vs 5 min read

Condensed

93%

972 → 69 words

Want the full story? Read the original article

Read on Tech Xplore