Revolutionary 3D-Printed Device Enhances Tissue Engineering Precision

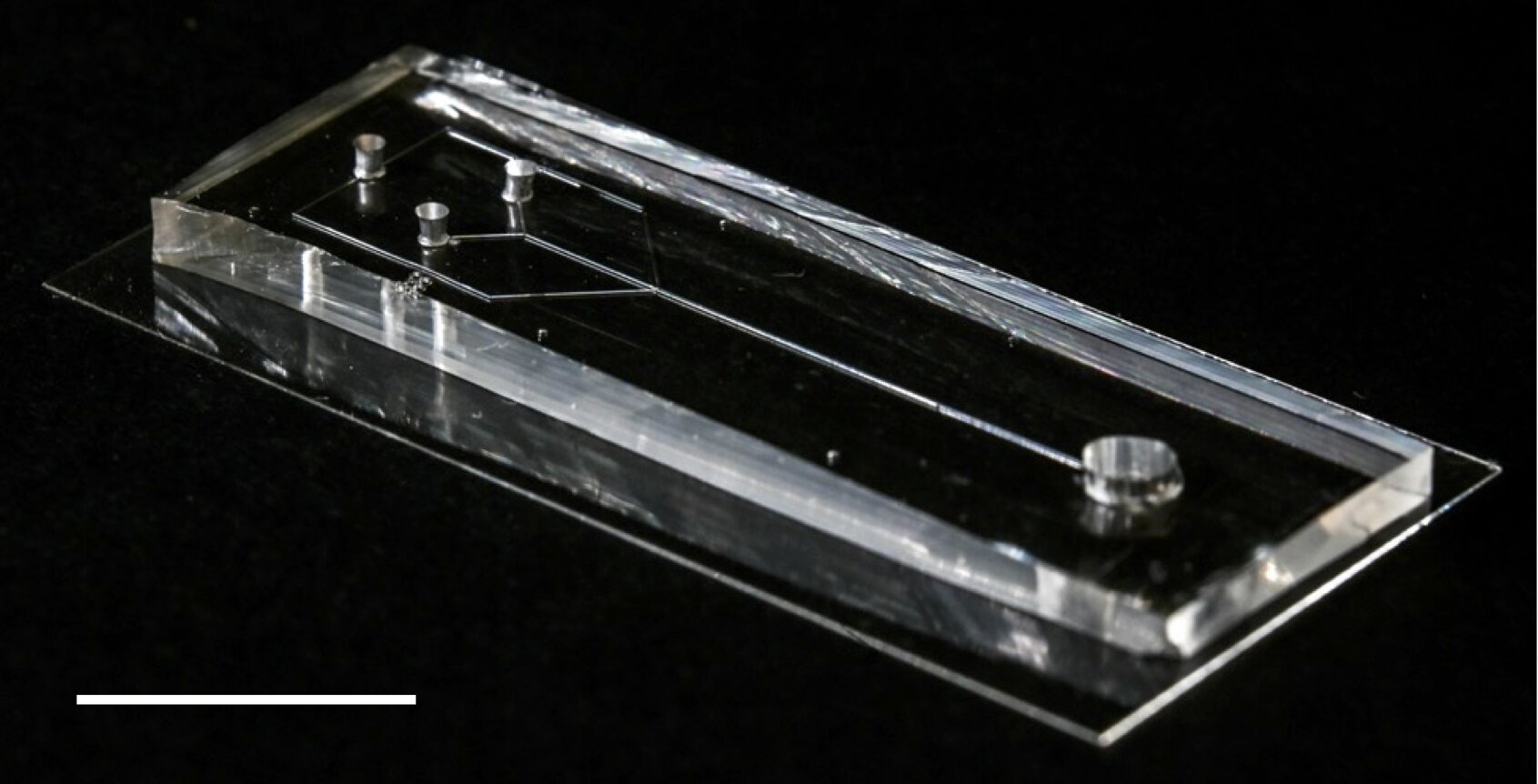

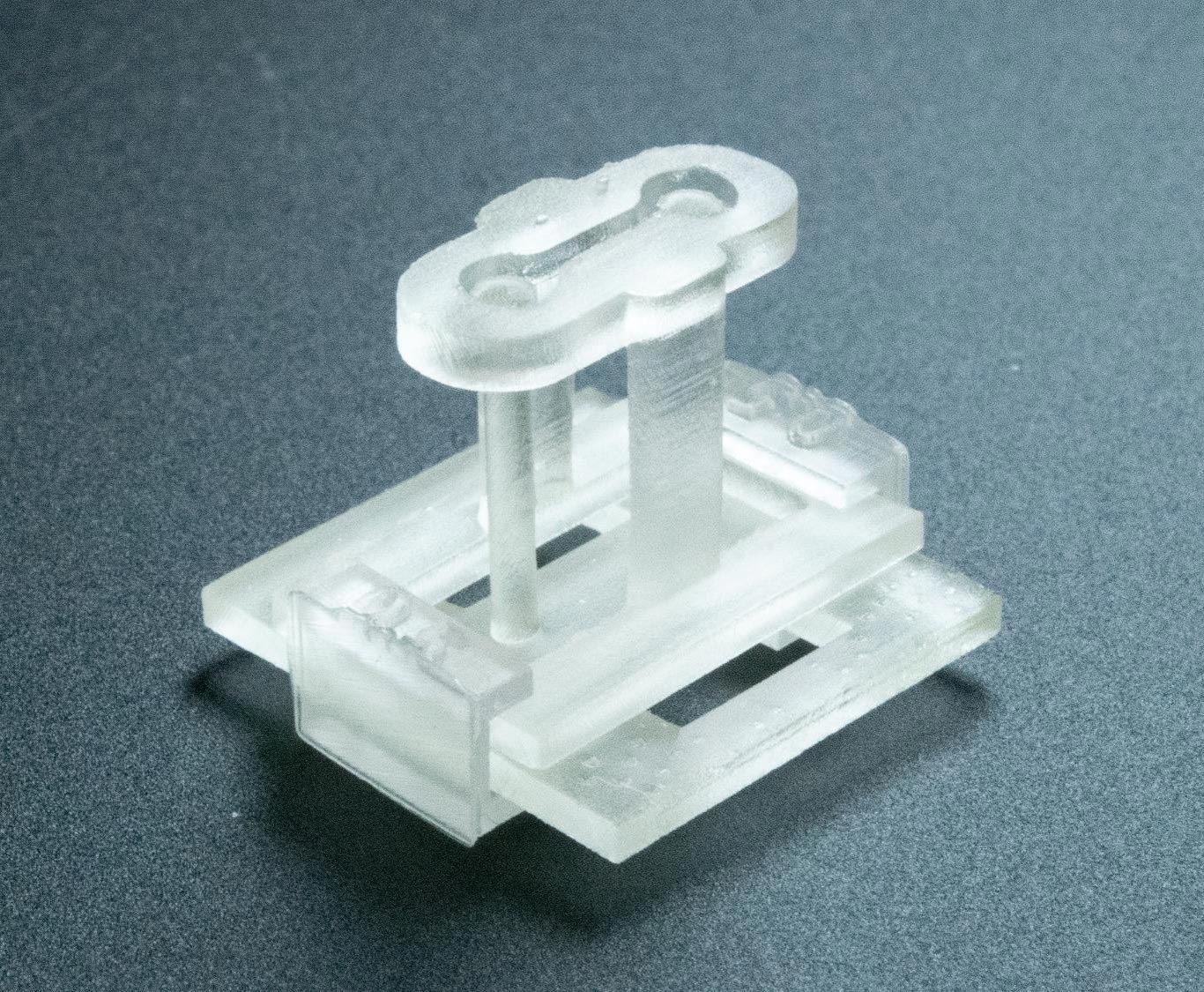

A tiny 3D-printed device called STOMP significantly enhances the precision and complexity of tissue engineering, enabling better modeling of human tissues and diseases by allowing precise cell patterning and interfaces, with potential applications in studying complex biological interactions.