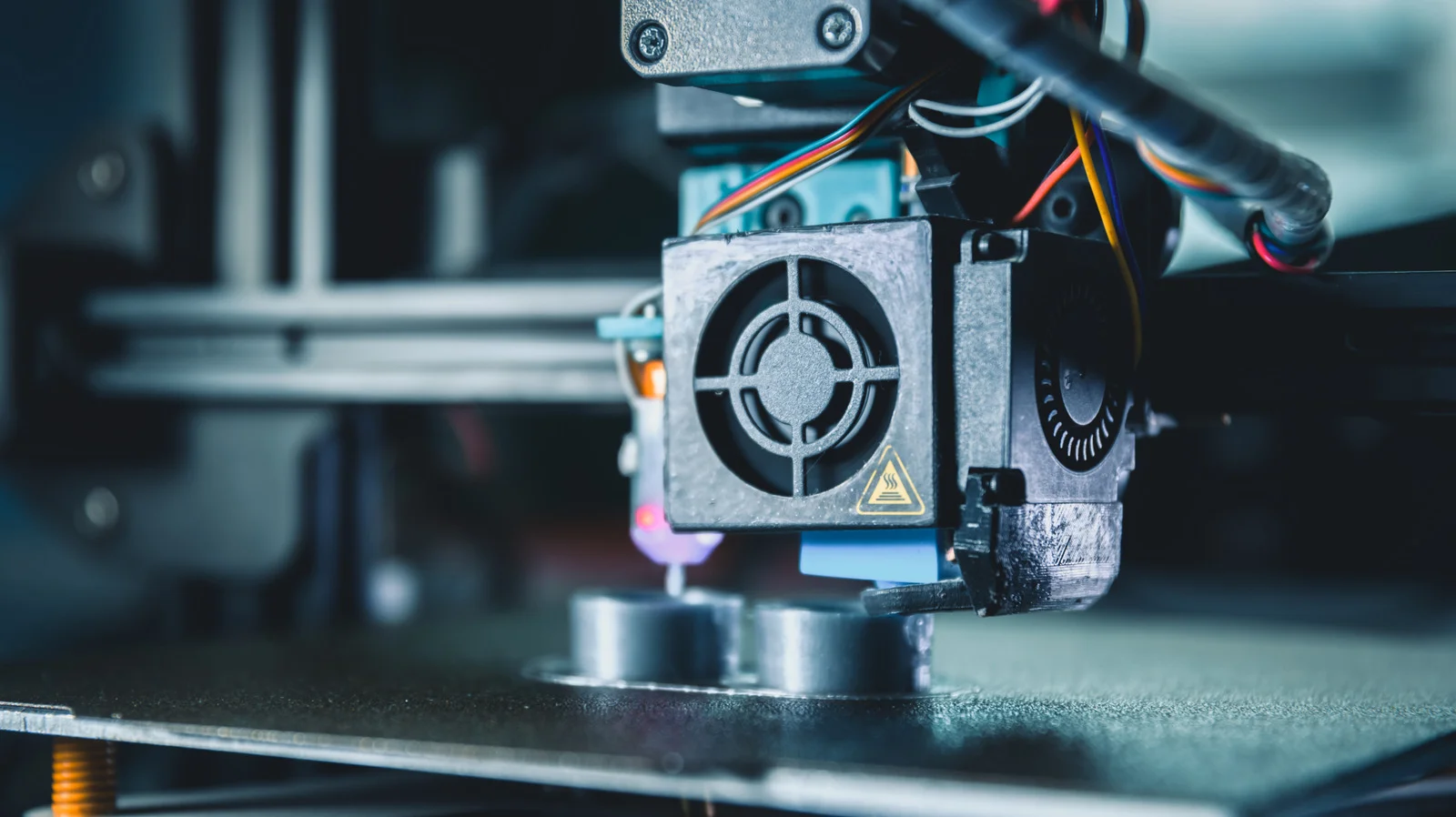

3D-Printed Cemented Carbide Outshines Steel in Hardness

Hiroshima University researchers used additive manufacturing to produce tungsten carbide–cobalt cemented carbide via 3D printing, achieving hardness above 1,400 HV—far harder than common steels. The method softens alloy elements rather than fully melting them, delivering a tougher, more wear-resistant metal with less waste, with potential uses in repairing cracks and strengthening construction; the research will be published in the April 2026 issue of the International Journal of Refractory Metals and Hard Materials.