Revolutionary Laser Technology Makes Steel 3D-Printing More Affordable

TL;DR Summary

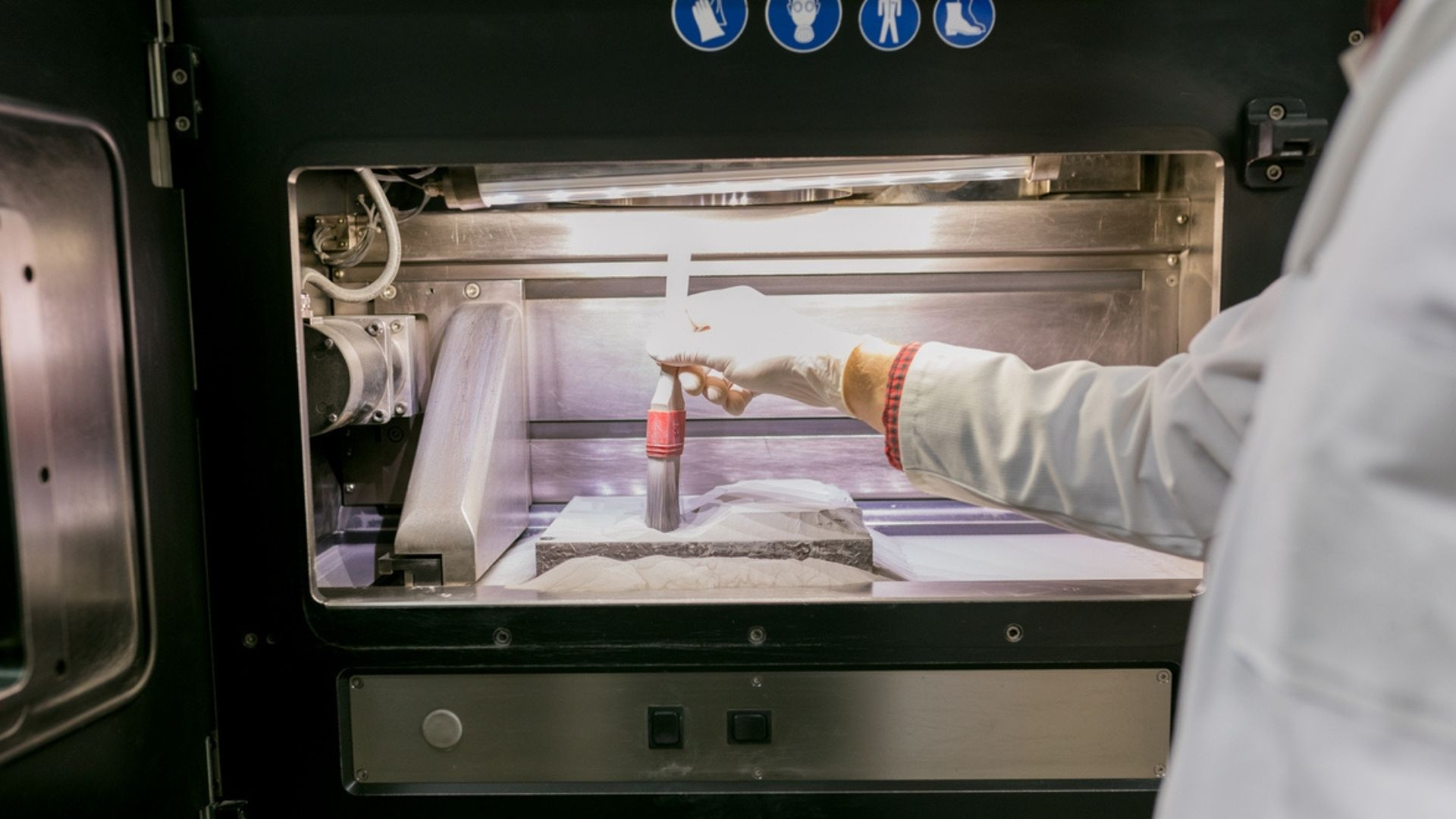

Researchers at the University of Cambridge have developed a new method for 3D printing metal that allows for structural alterations to be made during the printing process, reducing costs and increasing resource efficiency. The technique combines the benefits of 3D printing's ability to create complex forms with the traditional methods of engineering metal characteristics. The details of the method were published in the journal Nature Communications.

Topics:technology#3d-printing#cost-reduction#metal#resource-efficiency#technology#university-of-cambridge

- New laser enabled 3D-printing method makes steel more affordable Interesting Engineering

- Using lasers to 'heat and beat' 3D-printed steel could help reduce costs Tech Xplore

- Plasma Cutting And 3D Printing Team Up To Make Bending Thick Sheet Steel Easier Hackaday

- Using lasers to 'heat and beat' 3D-printed steel could help reduce costs University of Cambridge news

- View Full Coverage on Google News

Reading Insights

Total Reads

0

Unique Readers

0

Time Saved

0 min

vs 1 min read

Condensed

53%

141 → 66 words

Want the full story? Read the original article

Read on Interesting Engineering